Oil Spill Containment Concept Concept 2010

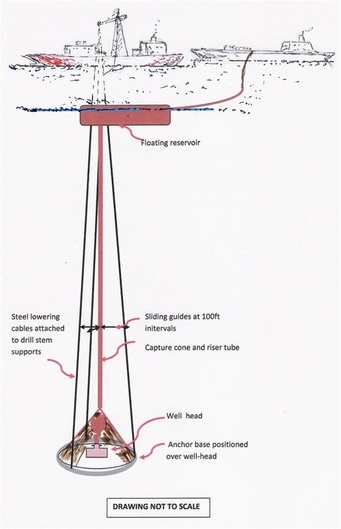

The free flowing oil and gas is funnelled through a large tapered cone and a 9ft – 10ft diameter flexible tube anchored over the well head. The riser tube is connected to a floating reservoir from which the crude oil is pumped into tankers.

The anchor base, consists of a 25ft diameter x 10ft deep collar comprised of steel and concrete with external attachments, a cone connecting mechanism and three cable/ drill stem connectors.

Three steel cables combined with drill stem supports lower with the base, capture cone and riser tube to the seafloor over the wellhead and hold the unit in place.

The capture cone and the riser tube are made in sections of tough synthetic, flexible fabric with ridged connecting rings and access ports each 100 ft. These rings also house 3 cable self-adjusting sliding guides.

The floating reservoir would be large enough to allow the oil and water to separate before being pumped out.

(All measurements are tentative)

The anchor base, consists of a 25ft diameter x 10ft deep collar comprised of steel and concrete with external attachments, a cone connecting mechanism and three cable/ drill stem connectors.

Three steel cables combined with drill stem supports lower with the base, capture cone and riser tube to the seafloor over the wellhead and hold the unit in place.

The capture cone and the riser tube are made in sections of tough synthetic, flexible fabric with ridged connecting rings and access ports each 100 ft. These rings also house 3 cable self-adjusting sliding guides.

The floating reservoir would be large enough to allow the oil and water to separate before being pumped out.

(All measurements are tentative)